PRODUCT

smart glass switchable

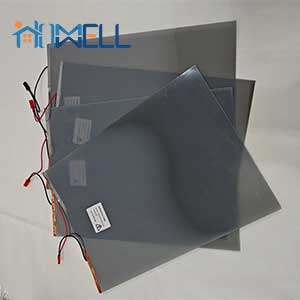

Brand Name: HOMEWELL

Product Name: Smart Film Switchable

Technique:Clear Glass, Tempered Glass, Smart Glass

Material:PDLC

Feature:self-adhesive

Thickness:0.44mm

Standard width:≤14cm/14-18cm

Working voltage:AC48V~65V/50Hz

Power consumption:≤5W/㎡

Lifetime:>80000h

| Brand | Homewell |

| Material | PDLC |

| Feature | self-adhesive |

| Function | privacy protection,heat insulation,explosion proof,decorative |

| Thickness | 0.45mm |

| Standard width | ≤14cm/14-18cm |

| Length | customize |

| Working voltage | AC48V~65V/50Hz |

| Power consumption | ≤5W/㎡ |

| Lifetime | >80000h |

1. Introduction: A Revolution in Transparency**

* Introduce the concept of dynamic light control and privacy.

* Define PDLC (Polymer Dispersed Liquid Crystal) film as a key technology for "smart glass".

* Brief overview of the advantages: dynamic control, privacy on demand, energy efficiency, modern design.

* Application range: from buildings and cars to healthcare facilities and home.

**2. What is PDLC Film? Basic Definition and Essence**

* Clarify: It is a multi-layer "sandwich" film installed *between* the panes of glass (usually DGU or triplex), rather than surface-bonded.

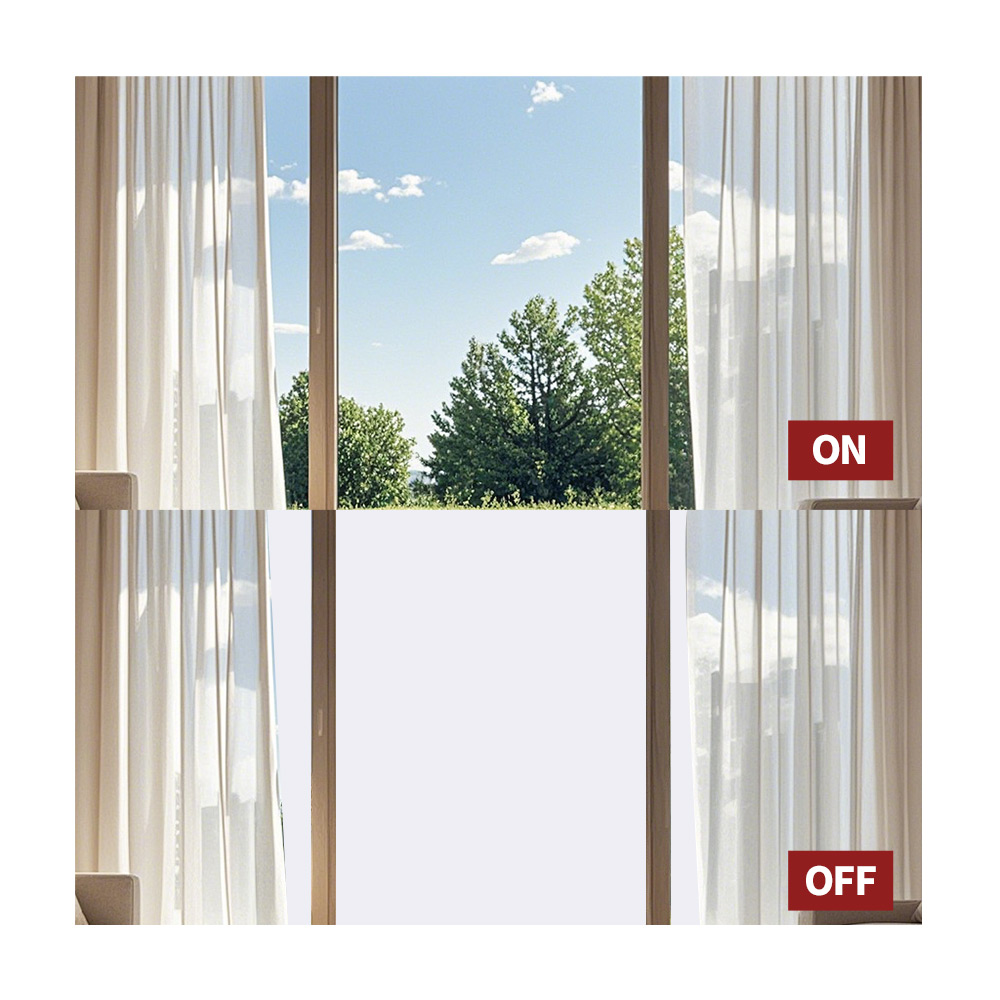

* Key property: Switching between **transparent** state (when energized) and **diffuse, cloudy/opaque** state (when not energized).

* Difference from SPD/Electrochromic: Faster switching, lower cost, better opacity in the "off" state, but no gradient dimming or full opacity.

**3. Disassembly of the Structure: Layer by Layer**

* **PET Base Films:** Thick, stable plastic layers (usually 2), providing mechanical strength. Special coatings for better strength and durability.

* **ITO (Indium Tin Oxide) Conductive Layers:** Applied on the PET layers. Transparent, but electrically conductive. Critical for applying an electric field.

* **PDLC Active Layer (Heart of the Technology):**

* Composition: Liquid crystal droplets dispersed evenly in a polymer matrix.

* Manufacturing process: Polymerizing emulsion (PIPS) or heat curing.

* Droplet size and distribution: Key to optical properties (opacity, transparency).

* **Adhesive Layer (OLA):** Special, optically transparent adhesive. Bonds the PDLC layer to the inner ITO/PET layer. Provides strong adhesion and durability.

* **Protective Separator Films:** Temporary coating, removed during installation.4. Principle of Operation: The Science Behind the Magic**

* **Stress-Free State (Off):**

* Liquid crystal molecules are randomly arranged.

* The refractive index of liquid crystals does not match that of the polymer.

* Result: Reliable light scattering in all directions - **opaque, opaque glass**. Privacy and glare reduction.

* **Powered State (On):**

* The applied electric field aligns the liquid crystal molecules parallel to the field.

* The refractive index of the liquid crystals (regular) now matches that of the polymer in the direction of light.