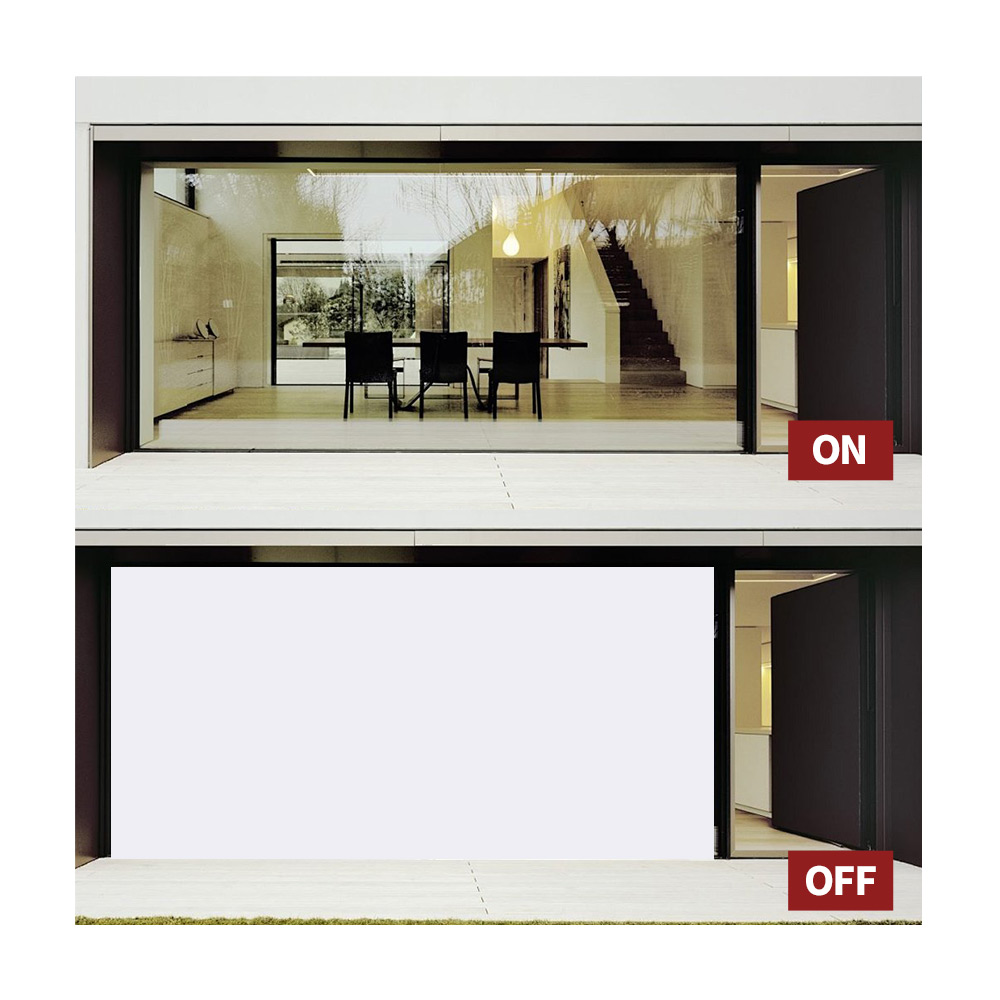

PRODUCT

| Brand | Homewell |

| Material | PDLC |

| Feature | self-adhesive |

| Function | privacy protection,heat insulation,explosion proof,decorative |

| Thickness | 0.45mm |

| Standard width | ≤14cm/14-18cm |

| Length | customize |

| Working voltage | AC48V~65V/50Hz |

| Power consumption | ≤5W/㎡ |

| Lifetime | >80000h |

Optimization of manufacturing processes and research into new polymer materials aim to reduce costs and improve performance. Larger panels, up to several square meters, have become possible, meeting large-scale architectural needs. Reducing environmental impact and improving the recyclability of materials are also receiving special attention.

**Maintenance, Care and Lifespan**

Maintenance of PDLC films is relatively simple. Cleaning the surface is recommended with a soft, lint-free cloth and mild soapy water or a special ammonia-free glass cleaner. The use of sharp or abrasive materials and strong solvents should be avoided, as they may damage the surface or electrical connections. Electrical components, especially connectors, require protection from moisture and direct immersion in water.

The lifespan is fundamentally influenced by environmental factors and frequency of use.

In commercial and display applications, PDLC film can transform transparent surfaces into interactive displays. In shop windows, transparency and projected images or advertising messages can be alternated. In exhibitions and museums, it can be linked to dynamic content, while in restaurants and bars, it can regulate the atmosphere. In the healthcare sector, it is used in the design of hospital patient rooms, examination rooms and psychotherapy rooms, where the combination of visual separation and natural light has a healing effect. In educational institutions, it can form dividers in lecture halls and libraries, while creating a modern learning environment.

**Installation Techniques and Control Systems**

The application of PDLC films can be achieved using several technologies. The most common solution is lamination onto existing glass surfaces. In this case, the film is attached to the glass panel using special UV-stable adhesives, even during renovation projects. Another common method is integration into double glazing. Here, the PDLC active layer is sandwiched between two glass panes, the edges are sealed airtight and the gap is often filled with a noble gas such as argon or krypton to improve thermal insulation. Here, it is primarily used in office partitions, conference rooms, administrative offices and private areas of healthcare facilities, where a combination of visual privacy and natural light is an essential requirement. In the case of skylights and ceiling lighting elements, it allows the control of excessive sunlight and heat ingress. In facade applications, especially on south-facing buildings, it results in significant energy savings.