PRODUCT

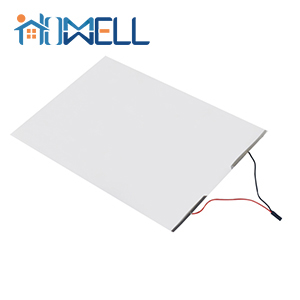

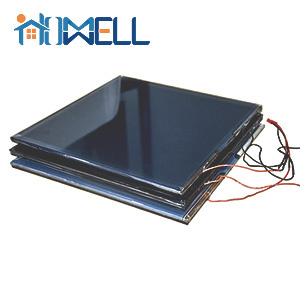

Non-Adhesive Smart Film is made of 2 layers of transparent conductive ITO films with polymer dispersed liquid crystal in between.it’s also called PDLC film ,smart window film,or glass film. Our R&D team owned pantent formulation in ITO film&PDLC film, the leading supplier and manufacturer in China.

Smart PDLC film will become vaporous due to the disordered arrangement of liquid crystal molecules after turning off the power.

On the contrary, when the power is on, neatly organized molecules will make smart film present transparency.

Smart Film is widely used in the laminated smart glass. Our cooperated glass factory world-wide imported them monthly.

The most common technologies used in smart glass are:

Electrochromic Technology: This type of smart glass contains a thin layer of materials that change their optical properties when an electric current is applied. When a voltage is applied, the glass darkens or becomes opaque, blocking the passage of light. Conversely, when the voltage is removed, the glass returns to a transparent state.

Polymer Dispersed Liquid Crystal (PDLC) Technology: PDLC-based smart glass consists of a layer of liquid crystals suspended in a polymer matrix. When an electric current is applied, the liquid crystals align and allow light to pass through, making the glass transparent. When the current is switched off, the liquid crystals scatter and block the light, making the glass opaque.

Suspended Particle Device (SPD) Technology: SPD smart glass contains tiny particles suspended in a liquid or film layer. When an electrical charge is applied, the particles align to allow light to pass through, making the glass transparent. By adjusting the voltage, the particles can be rearranged to block light, making the glass opaque.

|

Photoelectric Performance PNLC Smart Film |

||

|

Items |

ON/OFF |

Test Methods/Standards |

|

Operating voltage |

ON 60V |

Multimeter/ Voltage Regulator,WGW |

|

Power consumption |

ON avg 4-6W/m² |

Multi-parameter electric measuring instrument |

|

Viewing angle |

OFF 160°+1° |

Visual Inspection |

|

Uv blocking rate |

ON ≥ 85% |

Optical transmittance tester |

|

Infrared blocking rate |

ON ≥ 60% |

|

|

Response time |

ON ≤ 200ms |

Liquid crystal parameter |

|

OFF ≤ 220ms |

||

|

Operating temperature |

-- -20°C ~ 85°C |

constant temperature and humidity testing machine |

|

Lifetime |

-- 10 -15 years |

GB18910.5-2008 |

|

Switching times |

-- ≥2 million times |

Self-made on/off tester |

|

PNLC smart film is driven by AC power, fogged and translucent when power is added, colorless and transparent when |

||

Product Function

1) Privacy Protection :

The biggest function of Our pdlc film is privacy protection,which can control the glass between transparent and opaque.It can protect your privacy by our smart film

2) Projection Screem:

Our Pdlc film can be used as a good projection screen, in appropriate light environment, if choose high lumen projector, the image of projection effect is very clear(suggest use rear projection mode).

3) Safety Protection

Our pdlc film thickness is about 0.36mm. When installed on your glass window,It can adhensive your window closely, When the window are broken, The film can avoid the window glass flying around and hurt others,

4) Environmental Protection:

Our PDLC film attached on the surface of glass,Which can resist heat over 98% UV and over 95% infrared ray. In order to reduce thermal radiation, it requires shielding partial infrared ray. While if shielding UV can protect indoor furnishings not fade, aging and so on, and protect people against the disease by ultraviolet radiation.