PRODUCT

| Brand | Homewell |

| Material | PDLC |

| Feature | self-adhesive |

| Function | privacy protection,heat insulation,explosion proof,decorative |

| Thickness | 0.45mm |

| Standard width | ≤14cm/14-18cm |

| Length | customize |

| Working voltage | AC48V~65V/50Hz |

| Power consumption | ≤5W/㎡ |

| Lifetime | >80000h |

Environmental protection, energy saving, safety, heat preservation, and anti-condensation. High UV resistance, it can block over 99% of ultraviolet light. While not leaking visible light into the room, it isolates a large amount of ultraviolet light to prevent discoloration and aging of decorations and furniture. It can also protect people from diseases caused by excessive ultraviolet radiation. The core of PDLC technology lies in the interaction between light and matter at the microscopic level, exploiting the unique properties of liquid crystals. The film is a multilayer sandwich of extreme precision engineering:

Central Functional Layer: This is the active core. It consists of a transparent polymer matrix (typically a thermoplastic or photopolymerizable polymer) within which microscopic droplets (typically 1-10 microns in diameter) of nematic liquid crystals are uniformly dispersed. These liquid crystals possess anisotropic optical properties, meaning their interaction with light depends heavily on the orientation of their elongated (magnetized) molecules.

Transparent Conductive Layers (Electrodes): Adjacent to the functional layer are two very thin layers of transparent conductive material, almost always made of ITO (Indium Tin Oxide). These layers act as electrodes.

Support/Barrier Layers: The outer layers are generally made of high-strength, high-transparency PET (Polyethylene Terephthalate). These layers provide mechanical stability, protect the inner layers from moisture, oxygen, and physical damage, and often include adhesives for application to glass.

The operating principle is based on the application of a controlled electric field to the ITO electrodes:

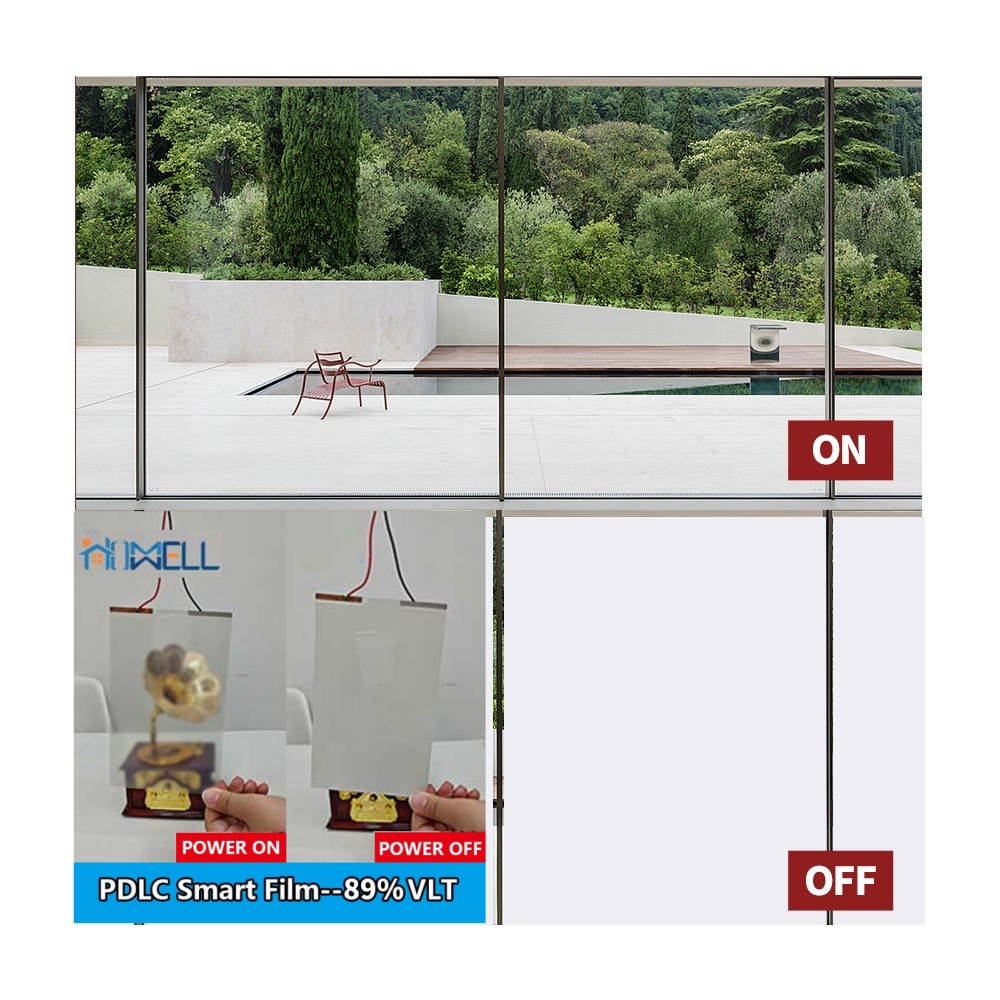

OFF State (Not Powered - Opaque/Private): In the absence of electrical voltage, the liquid crystal molecules within each droplet are randomly oriented. Their optical axes (the direction along which the refractive index is maximum) point in random directions. As light passes through this disorganized layer, it encounters countless interfaces between the polymer (refractive index n_p) and the liquid crystal (refractive index n_cl). Because the optical axes are random and because there is a difference between n_p and n_cl (especially for light polarized perpendicular to the optical axis), the light undergoes intense multiple scattering.